How Superior Oilfield Rentals oilfield cuts downtime on-site

Wiki Article

All Regarding Oil Field Equipment and Pipeline Equipment: Trick Insights and Important Info

Oil field equipment and pipeline systems play a pivotal duty in the oil and gas market. They are essential for the effective removal and transportation of hydrocarbons. Key parts, such as drilling rigs and storage space tanks, directly influence operational success. Improvements in innovation pledge to boost safety and security and efficiency. Comprehending these components is essential for anyone associated with or curious about this intricate market, as it sets the phase for deeper exploration of industry practices.

Overview of Oil Field Equipment

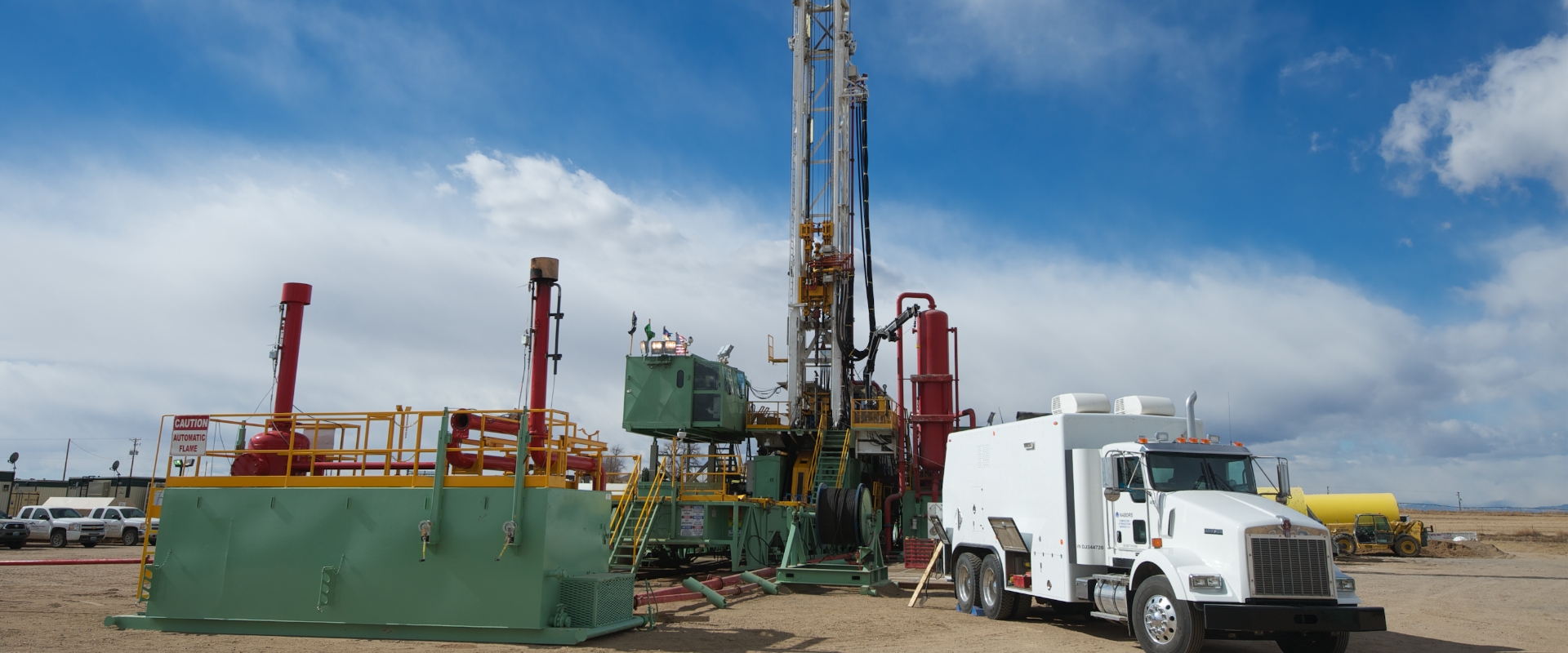

As the need for oil remains to expand, recognizing the devices used in oil areas ends up being increasingly essential. Oil field equipment incorporates a wide array of machinery and devices essential for exploration, removal, and processing. Key parts include piercing rigs, which are crucial for reaching oil tanks, and production devices, such as separators and pumps, that facilitate the removal procedure. Superior Oilfield Rentals Texas. Furthermore, tank play a considerable duty in holding crude oil prior to transport. Security equipment, including blowout preventers and stress gauges, guarantees functional safety and effectiveness. Each item of tools functions cohesively to maximize production and maintain efficient operations. Experience with this devices is essential for specialists in the industry to guarantee effective procedures and adherence to safety requirementsKinds Of Drilling Rigs and Their Applications

Drilling rigs work as the backbone of oil extraction operations, with numerous types designed for particular geological problems and functional demands. The most common types consist of rotary drilling rigs, which use a revolving drill bit to pass through the planet, and cable tool rigs, understood for their percussion drilling method. For offshore operations, jack-up rigs and semi-submersible rigs provide stability and assistance in aquatic atmospheres. Furthermore, directional boring rigs allow drivers to pierce at angles, reaching down payments that are not up and down available. Each gear type has special benefits, maximizing performance and safety and security based upon the boring atmosphere. Selecting the proper rig is vital for making best use of resource removal while reducing environmental impact and functional prices.

Crucial Pipeline Equipment and Their Features

Pipeline facilities is vital for the transportation of oil and gas from removal sites to refining facilities and end-users. Numerous essential equipment components facilitate this procedure. Pipelines themselves act as the main conduits, developed to endure high pressure and harsh materials. Pump stations are essential for maintaining flow by improving stress along the pipeline. Valves play an important duty in regulating circulation and isolating areas for maintenance. Additionally, installations and ports assure safe and secure joints between check this site out pipeline sections. Checking systems, including circulation meters and pressure sensing units, are essential for finding leaks and maximizing circulation prices. Pigging equipment is used for maintenance and cleansing, securing pipeline stability and effectiveness. With each other, these elements form the foundation of a reputable pipeline system.Innovations and Technologies in Oil and Gas Equipment

Security and Maintenance Practices in the Oil Sector

While the oil industry has made substantial strides in modern technology and efficiency, the significance of robust safety find out and security and upkeep practices can not be overemphasized. Efficient safety and security protocols are important to secure employees and the setting, decreasing the danger of crashes and spills. Regular examinations and upkeep of tools aid recognize potential issues before they intensify, ensuring operational integrity. Training programs for workers are essential, emphasizing the significance of security awareness and emergency reaction procedures. Additionally, adherence to industry regulations and requirements cultivates a society of safety and security. Applying innovative monitoring technologies can further enhance maintenance techniques, allowing for real-time assessments of equipment problems. Eventually, focusing on safety and security and upkeep is important to the sustainability and success of the oil industry.Regularly Asked Questions

What Are the Environmental Impacts of Oil Field Equipment?

The environmental influences of oil field equipment include environment damage, water contamination, and air pollution (Superior Oilfield pipeline equipment rentals). Additionally, equipment breakdown can result in spills, detrimentally impacting wild animals and ecosystems, highlighting the demand for strict laws and tracking

Exactly How Is Oil Field Equipment Transferred to Remote Locations?

Transporting oil field equipment to remote locations typically entails specialized automobiles, helicopters, or barges. Logistics business coordinate courses, guaranteeing equipment arrives securely and successfully, taking into consideration surface and accessibility to lessen hold-ups and make the most of performance.What Governing Criteria Govern Oil Field Equipment?

Regulative criteria controling oil field equipment mainly include safety, environmental management, and functional performance standards. Agencies such as OSHA and EPA enforce these policies to ensure secure techniques and minimize ecological impact in oil removal operations.What Skills Are Needed to Operate Oil Field Equipment?

How Do Oil Rates Impact Equipment Demand and Usage?

Oil prices significantly influence equipment demand and use. Greater prices usually lead to boosted expedition and production activities, driving need for machinery. Alternatively, lower prices may lead to reduced operations and reduced requirement for equipment.Report this wiki page